Kevin, Karolyn, and son Daniel Kaster of Kasters Kustom Cutting

Kevin, Karolyn, and son Daniel Kaster of Kasters Kustom Cutting

Thirty years ago, Kevin and Karolyn Kaster bought a small wood mill to cut up a downed tree. ("It was too nice for firewood," Kevin says.) The Mulino, Oregon, couple's neighbors found out about their new purchase. Soon, Kevin and Karolyn were driving the portable mill around northern Oregon, transforming property owners' trees into hardwood floors, furniture, and building materials.

Kasters Kustom Cutting stays in one place now. But personal relationships are still at the heart of their work. For one, sons Daniel and Stephen have joined Kevin and Karolyn in the family business. And they know most of their suppliers. "The furthest source for our logs is maybe 60 miles away," says Kevin.

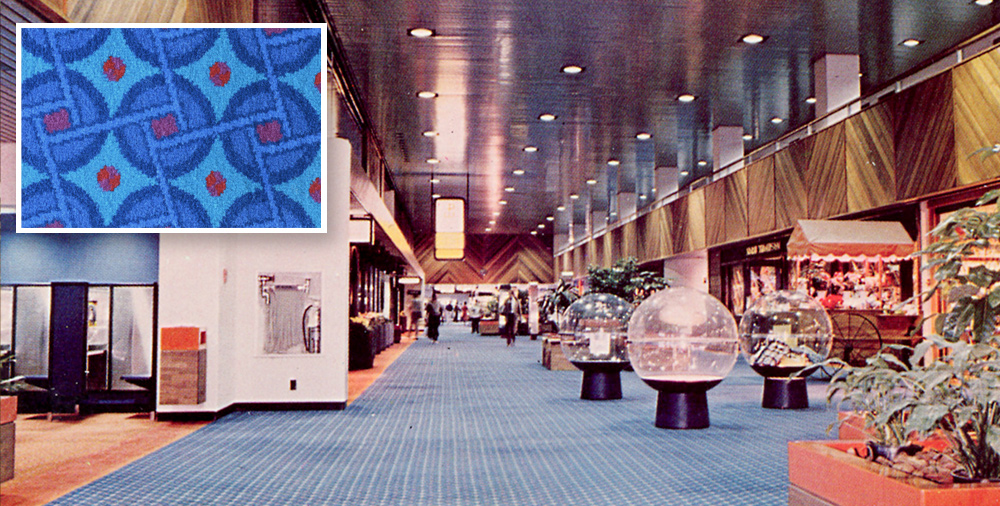

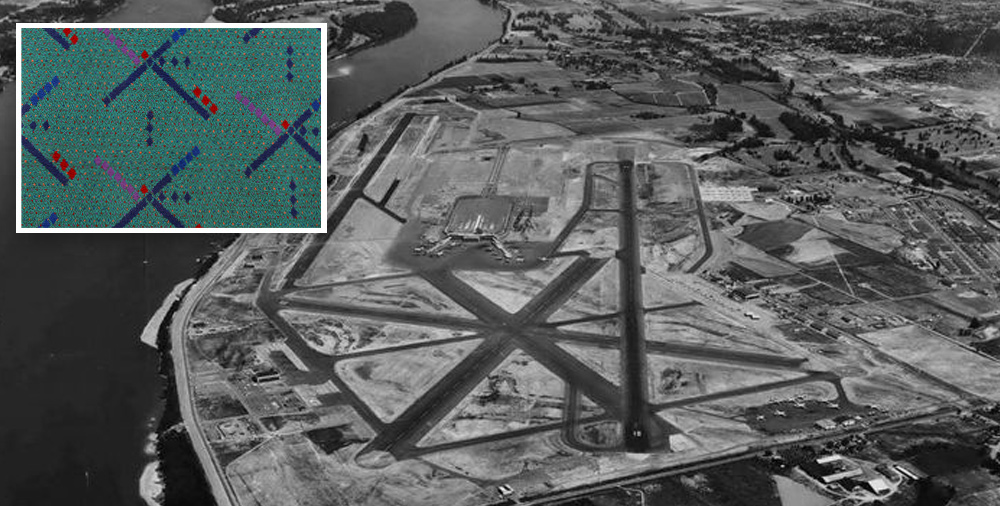

The Port of Portland partnered with Kasters Kustom Cutting to supply local, sustainably sourced Douglas fir for the new ceiling of the main terminal. We called up Karolyn and Kevin to find out how and why they do what they do. (This interview has been condensed and edited for clarity.)

How'd you get connected with the airport?Kevin: The port wanted wood from small woodland owners. We're small enough that, as the logs came in from Hyla Woods or Camp Namanu, we could trace each log through the mill. We can tell you exactly where each three-by-six board came from.

You're a board member of the Clackamas Forest Farm Alliance and Portland's Build Local Alliance. Why are you so committed to local wood?Kevin: People want to support local industries and local people. They like to know that their wood came from within a few miles of their project. Nothing against people in New York or California, but you feel a little better when you know your money is staying here, going to a family who lives down the road.

Karolyn: We also want to support the forests. With well-managed forests, we can grow and harvest plenty of wood. We can create projects, whether that's buildings or countertops, with wood that can last a long time. And then we can create jobs that make a profit. It all can work together.

Kevin: There's one guy we know in the Farm Forestry Association who added gravel and put some stumps in his streams. Now he's got salmon coming up that creek that haven't been there for close to 20 years. If we can sell a product and kick some extra money back to a forest owner so he can put gravel in his streams and not have to clear-cut, we enjoy that. That's a good thing.

Was sourcing some of the wood for the terminal’s roof a big effort for Kasters?Kevin: This was a nice-sized project. I think we cut over 50,000 board feet. A mill our size normally cuts from 1,000 to 3,000 feet in a day.

With [names a large nearby mill], they're automated. Their computer reads each log to get the best yield from it. Our computer is named Jim.

You also worked on a second airport project: the Douglas fir sculpture Ben Butler created in 2021 for the walkway to the Rental Car Center.

Kevin: We were the supplier of the wood. We acquired timbers from buildings that were being torn down, milled them to size, and sent them to Tennessee. There, Ben did the cutting and carving.

What did it mean to you, personally, to work on the airport?Karolyn: It has been nice for us to know that others can experience the beauty of the natural resource that we're surrounded by.

Kevin: It was always a great feeling to pull into someone's garage, and they had a pile of logs that were useless to them. When we left, they'd get a pile of lumber. We'd get pictures of the things they made and invites to open houses. It's a little different than just selling lumber.

Everybody we worked with on this job was great, from the architects to the people from the Port. When we came down to tour the roof on the building lot, our tour guide was from the Port. When you do projects like this, you get to know people more personally than if you simply ship stuff away.