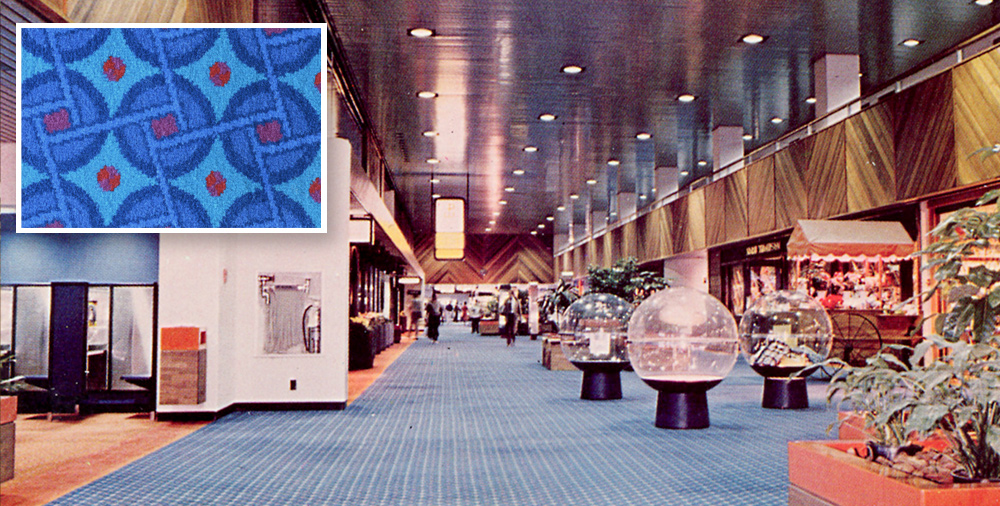

Sara Schmidt and Pratt + Larson’s rose mural near Gate D5.

Sara Schmidt and Pratt + Larson’s rose mural near Gate D5.

Quick update: This article was written in 2022. The new PDX (which has even more tile mosaics) is here! Want to meet it?

It's probably been a while since anyone has told you to go the bathroom.

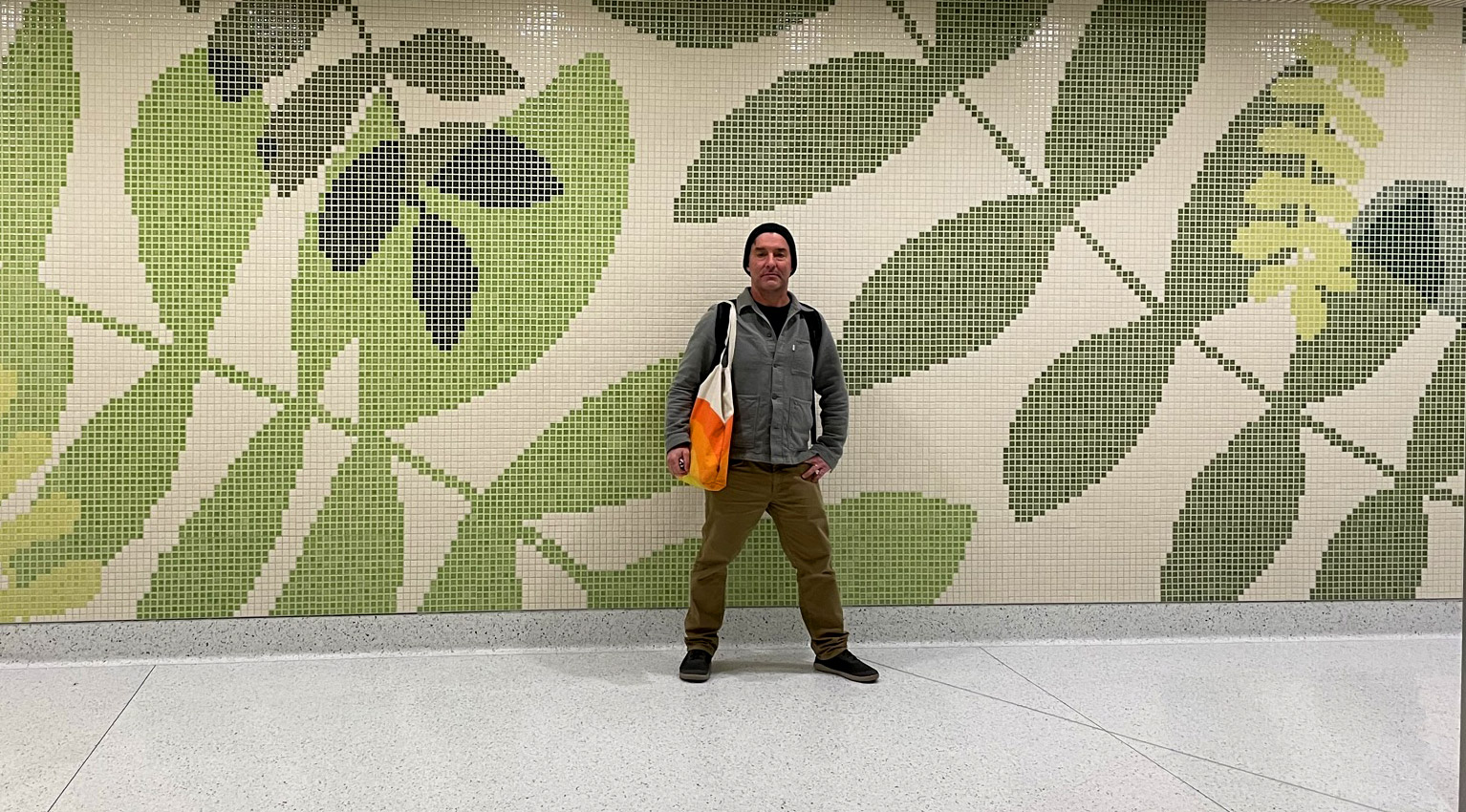

But if you're traveling through Concourse B or passing Gate D5 in Concourse D, we suggest you take a detour to look at the bathroom. On the inner wall of the entrance, you'll find two of PDX's newest treasures: tile mosaic murals designed by Sara Schmidt and fabricated by Pratt + Larson, Portland-based tile makers. (The Concourse B mural is a pattern of ferns, while the Concourse D mosaic is a field of roses.)

You’ll spot Sara Schmidt and Pratt + Larson’s fern mural at the entrance to the Concourse B bathrooms.

You’ll spot Sara Schmidt and Pratt + Larson’s fern mural at the entrance to the Concourse B bathrooms.

These artworks, installed in 2021, are not just a marvel to look at. Each mosaic showcases the excellence of local artisanship, not to mention an astounding amount of work.

How much work? Pratt + Larson owners Belle Iskowitz and Anthony Asch, longtime employees who bought the Inner Southeast factory from founders Michael Pratt and Reta Larson in 2017, came up with some figures:

That's the total number of 1-inch-by-1-inch ceramic tiles used in the two murals, which cover more than 1,000 square feet of wall space in total.

Every single tile was made to order in the company's three-story factory, using ceramic clay produced specifically for Pratt + Larson by Georgie's Clay & Ceramic in Northeast Portland.

Working in wet clay, the tile makers stamp out 100 one-inch-by-one-inch tiles at a time using a pneumatic cutter. Teams working quickly can stamp out 40,000 tiles a day, which then spend several days drying before being bisque-fired in large kilns that keep the basement warm even on the chilliest day.

Once the tiles cool, workers patiently arrange the 1-by-1-inch tiles in metal frames before bringing them up to the factory's third floor for glazing.

Pratt + Larson makes tiles to order for every project, and clients can choose from hundreds of colors in their library of glazes. When Sara Schmidt was designing the rose and fern mosaics, she worked with Arthur Moloian, director of business development at Pratt + Larson, for several months to select 19 glossy glazes. The designer then created complex maps to show the team how each of the 147,168 tiles should be arranged.

To give each tile its glossy top coat, the glazing team mixes up precise recipes of frits (partially fused glass) and minerals to create the glazes. One worker hand-sprays the trays of tiles with the glaze, and then a second wipes off any excess—from every single tile. The tiles are fired for a second time in small electric kilns to melt the glazes.

Belle and Anthony estimate that 20 sets of hands touched each tile produced for the murals. That included Pratt + Larson’s quality assurance team, who inspected each tile, as well as the mosaic team, who arranged the tiles into 1-square-foot sheets according to the diagrams Sara gave them.

It took even more sets of skilled hands to install the mosaic mural. A crew from Prestige Tile & Stone, an Aloha business owned by Nancy Bebek, worked with Sara on site to carefully arrange the sheets on the floor, making sure every piece was correctly aligned, before fixing the mosaic to the wall.

When Pratt + Larson's 75 staff members fly out of PDX, they now like to make a detour so they can take selfies in front of the murals.