Jason Koski, general superintendent at Hoffman-Skanska Joint Venture, has seen PDX’s new main terminal take shape from the very start. Not only has he led the on-site construction crews, he’s been in the planning meetings for six years, teaming up with architects, engineers, contractor partners, and Port staff to safely solve some of the most technical puzzles any of them have ever encountered.

As the new main terminal’s opening day approaches, we asked Jason about the first-time challenges the crew faced — and which ones he’s proudest of helping to solve. (Turns out, they’re the same ones.)

As Jason says, “This, by far, has been the job that I’ll look back on later in my career and say, ‘I was part of that.’”

This interview was edited for clarity and conciseness.

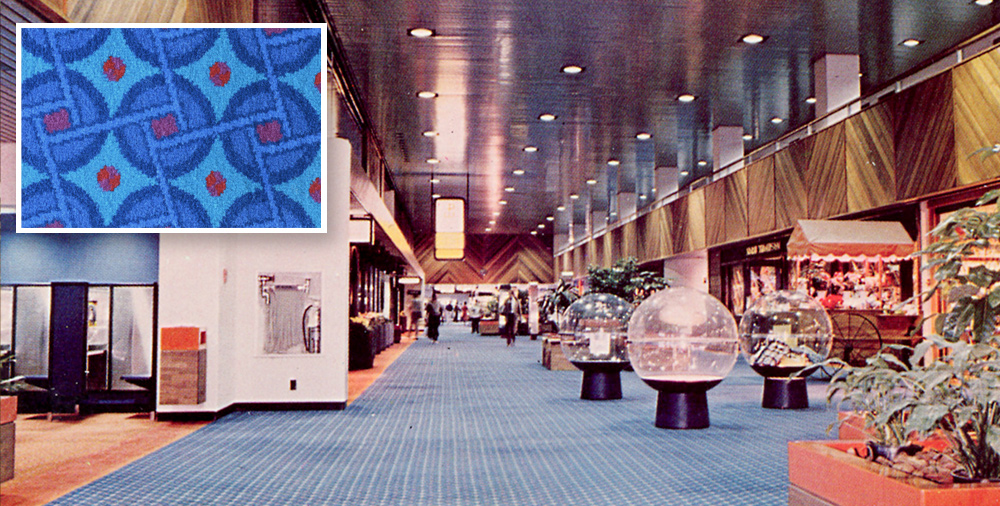

We hear that your first job was at PDX?Early in my career, I started as an apprentice carpenter. I had worked on three different projects, then I came to the airport in 1991. We worked on the TEN tower, which is the glass area above the north security checkpoint. It’s the tower we’re soon going to take down. Does that make you old when you’ve built something that you're now taking down? [laughs]

When did you start working with Hoffman Skanska on the new main terminal?I started at the beginning of 2018. We worked with the Port to develop the phasing for this project. That's where it started: figuring out how we're going to phase the work. Then we could revise the design and eventually start construction.

Have you ever worked on anything this complex?No! Because it's an occupied airport. This is a multi-employer site. It's not just an airport. It's a restaurant, a place of business where airlines work, a place where people travel for work. There's a lot for us to consider.

We're working right above and right next to the 1.4 million passengers who visit the airport every month, and keeping the facility running without damaging any systems. We go into the heart and lungs of the building — electrical and mechanical rooms that supply power, heating, cooling, water, for everything at the airport. Those systems we can't compromise, so you’re basically doing surgery.

Are there challenges that you're most proud of finding solutions for?Figuring out how to build the roof kept all of us up at night. More than one night!

Every time the team met, our saying was that we’d check our egos at the door, and roll up our sleeves to solve problems. We’d end every meeting by sharing what was keeping us up at night — and then we’d document each concern and address it. We wanted everyone to feel comfortable to say, “I'm worried about this.”

I think we worked the most on how to design, construct, and move the roof from the prefabrication yard onto the building. At the end of the day, we were able to place 14 sections of roof without impacting the airport’s operations.

Another thing that kept us up at night was how this exterior curtain wall would work, since it's the first of its kind. We're hanging the curtain wall from the roof [to ensure seismic stability]. We had to pre-load the roof every 10 feet to simulate the weight of the glass windows we were hanging, then take the weights off to install the glass. It was like a teeter-totter. Working in partnership with the designer, the engineer, the Port, and the contractors, we perfected a process that had never been done before.

You’ve been in the planning room since the beginning. What's it like to be there now, on site, as the terminal finally takes shape?This work is being done by an A team. For someone who's one of the leads on this project, I know what a great job everyone is doing and how important it is to thank all the people for what they do every week.

When you give a tour, and see [the terminal] through other people’s eyes, it reinvigorates you. It reminds you how great this thing is that you’re a small part of.