When ZGF Architects presented us with a proposal to build a nine-acre wooden roof over PDX’s new main terminal, we responded with a question: Can we source 2.6 million board-feet of Douglas fir in a way that is better for the land and better for our local communities?

Together, the team came up with a set of goals:

- All the wood would come from Oregon and Washington forests located less than 300 miles from PDX.

- We would source as much timber as we could from small landowners, community forests, and sovereign tribal lands, prioritizing landowners who were working to restore forest ecosystems.

- Inspired by “farm to table” cuisine, we tried to trace as much of the wood as possible from forest to frame, something few big construction projects have ever tried.

No one—in the United States, in fact!—had done this before at the same scale. It took two years and many, many phone calls to build a network of Pacific Northwest foresters, mill owners, brokers, truckers, and construction firms who could join our quest to trace wood from forest to frame.

Here’s how we did it

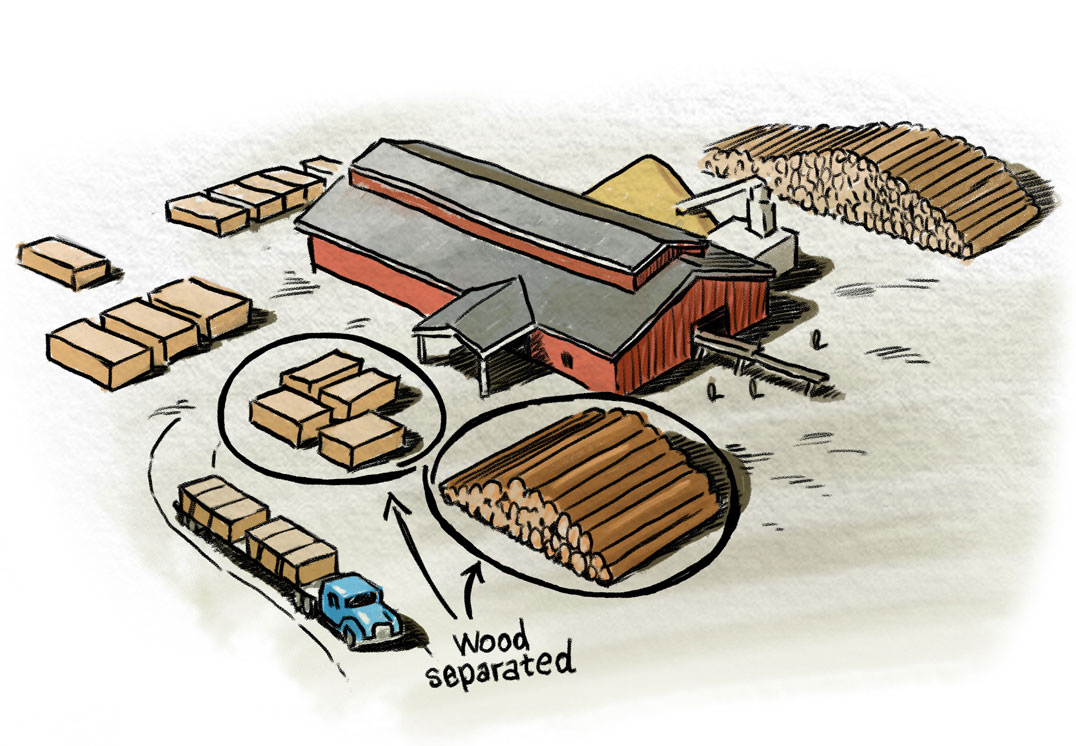

Traditionally, timber mills contract with forest landowners to clear-cut timber from large tracts of land. (The landowners also plant saplings to replace the 30-to-80-year-old trees they harvest.) Mills get logs from dozens of forests, and all that timber goes into massive piles before it’s cut into boards and dried in kilns.

The system is efficient. There’s little waste. However, by the time the lumber leaves the mill, there's no way to tell which forest it came from.

Three-fourths of the timber we sourced went above and beyond federal standards for ecological forestry. Some of the forest caretakers we worked with even thinned their trees with precision-cutting machines or cleared small (1- to 6-acre) plots. Methods like these give the remaining trees better access to water and light, increase biodiversity, and make the forests more resistant to wildfire and drought.

The mills that bought our forest-to-frame logs agreed to store and cut the wood separately from the rest of their supply—no small effort for efficient, fast-moving operations. Truckers then brought the boards to PDX’s fabricator and construction partners, who carefully labeled and stored all the wood destined for PDX’s roof and made sure it never mingled with other materials.

In the end, 100% of the wood in PDX’s new roof came from a 300-mile radius, and we can trace 30% of the timber back to its forest of origin. Our hope is that our efforts will make it easier for other major building projects to follow suit.

Most of all, we are grateful to the hundreds of people who cared for this wood every step of the way.

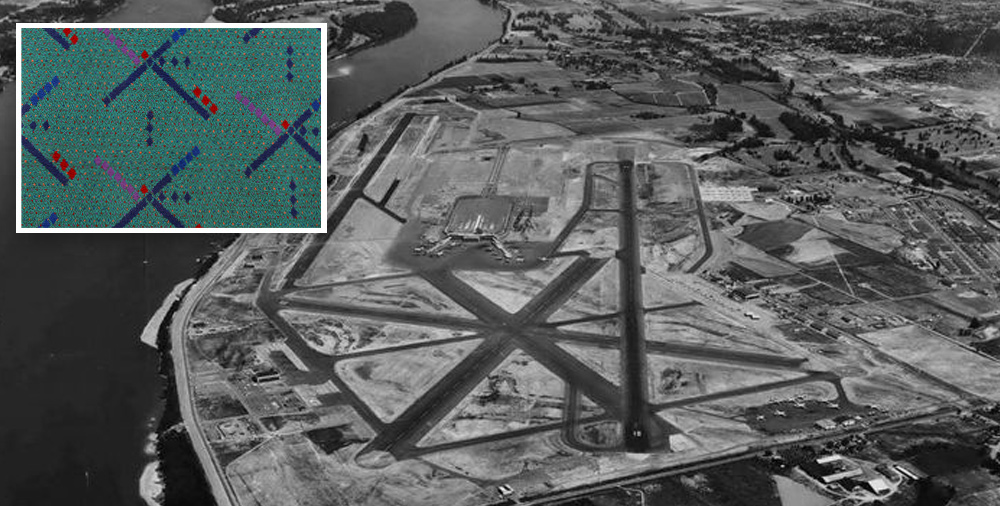

Mapping the ceiling from forest to frame

The ceiling lattice uses timber from just 11 local forests. Scroll around the map to see if it came from a forest near you:

Scroll around the map to see if the wood came from a forest near you.

Here's what this year will look like for PDX (and you!)

Finishing the Roof Construction

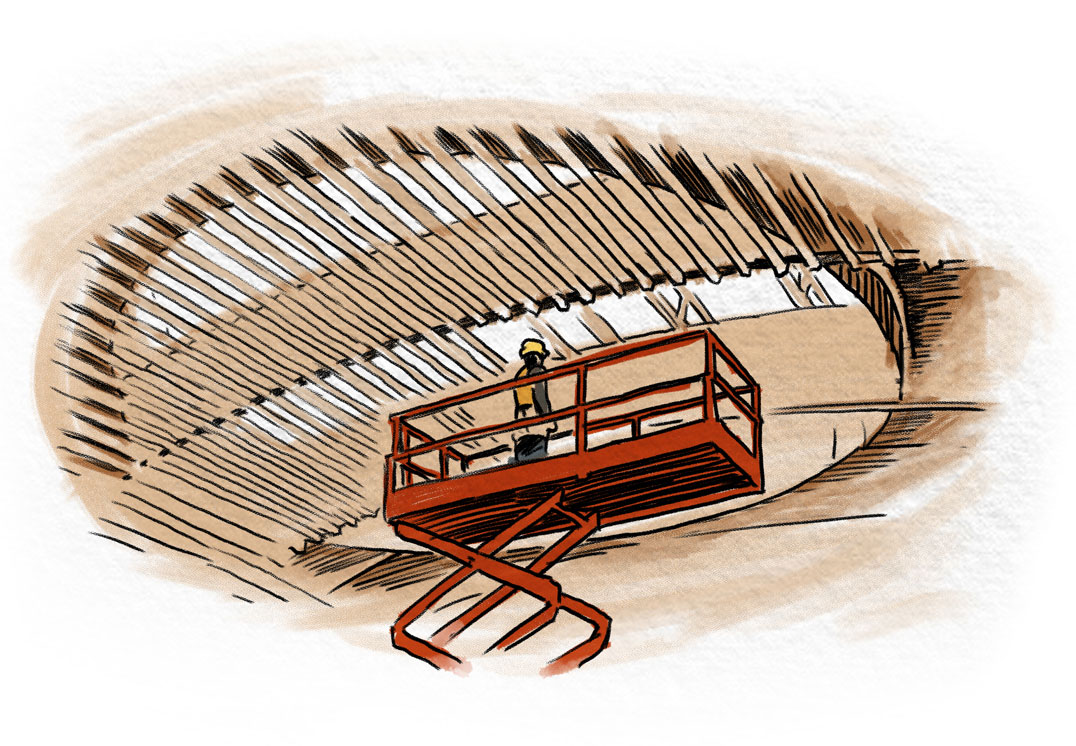

For the past year, we've built a nine-acre roof on a prefabrication lot to the northwest of the airport. The construction crews are now installing the last component—an intricate wood lattice, sourced from sustainable Northwest forests, that will eventually cover the interior ceiling.

What you'll see: If you drive along Marine Boulevard, you can glimpse the roof's dramatic swoops in the prefab lot.

Demolishing the Last of the Clocktower Plaza

Behind all those partitions in the pre-security area, construction crews have been hollowing out the back half of the main terminal. Starting in March, the exterior structure is also coming down to create a more open, spacious footprint. It may get noisy for a few months!

What you'll see: Not much, in fact. But when you’re in the ticket lobby and going through security, you may hear and feel what’s happening on the other side of those partitions. We're strategizing ways to counteract the sound, including free earplugs at the front doors and a sensory room in Concourse D.

Installing the Y Columns

Next, we’re erecting 34 giant steel Y-shaped columns to hold up the roof. Right now, construction crews are driving steel pilings deep into the ground to anchor these columns. Over the course of a few months, we’ll erect the Y columns one by one.

What you'll see: You probably won't notice—most are going up overnight behind the temporary walls. Late-night travelers will occasionally have to walk a few yards around an installation site.

Moving the Roof Into Place

Once the biggest section of the wood roof is fully assembled, the project team will break it back down into 20 "cassettes". During the summer and fall, Hoffman-Skanska and Mammoet will maneuver each cassette into place over the existing roof. It will take several days to place each cassette, and the work will happen overnight — depending on the section we’re placing, we may guide late-night travelers around a short detour.

What you'll see: Unless you're flying into PDX on a late-night flight, or camped out on Marine Drive at 2 a.m., you won't see much. If you walk to the ends of Concourse C or Concourse D and look back toward the main terminal, you'll catch a glimpse of the airport's new roofline.

Adding More of What We Love

Bonuses

Bonuses

In addition to the big projects, you’ll see a host of new amenities appear throughout the airport. A new play area in Concourse E. New art. New restaurants and cafes. (Lardo! Screen Door! Good Coffee!) You're almost guaranteed to encounter something new every time you visit the airport — and we're not talking barricades.

The entire project at a glance

Farewell to all that

Sometimes you have to say goodbye to the old in order to welcome the new. In 2019, we tore down Concourse A in order to build Concourse B. Frank talk: We haven’t missed it.

PNW-inspired designs revealed

Our team of local architects unveiled the designs for the airport’s main terminal: spacious, flexible, and green, with plenty of Pacific Northwest character.

Concourse E gets an expansion

The six new gates we added to Concourse E came with a few bonuses: more dining options, the new Tillamook Market, an installation from acclaimed artist Jacob Hashimoto, and stellar views of Mt. Hood.

Builders tackle some big challenges

In April 2021, we closed the Clocktower Plaza so our crews could bring the new main terminal to life. We also began building the wooden roof on a construction lot northwest of the airport.

Opening a Rental Car Center

Fall 2021

Fall 2021

Opened in November 2021, the Rental Car Center helps you get in and out of PDX faster. On the floors above, we've added 2,200 more parking spaces.

Welcoming the new Concourse B

Winter 2021

Winter 2021

The bigger, daylight-filled Concourse B replaces Concourse A, adding more Oregon flavor in the form of new art, Good Coffee drinks, and Screen Door fried chicken.

More flexible transit options

Fall 2023

Fall 2023

The new Transportation Plaza, located in the long-term parking garage, makes it easier to meet up with your taxi or rideshare driver — and eases congestion along Airport Way. TriMet has also completed major improvements to the MAX Red Line, and a new bike trail has made it safer and smoother to cycle to PDX.

Welcome to the new PDX

Fall 2024

Fall 2024

The new main terminal isn’t just greener and more spacious. It has larger security checkpoints and more places to eat and shop, as well as more art, music, and expansive views.

The main terminal is complete

Spring 2026

Spring 2026

Once we’ve finished the construction on the terminal’s north and south ends, you’ll find permanent exit lanes, new airline lounges, more all-user restrooms, and even more local shopping. Plus, the last temporary walls and detours go away for good!

Tom Strong - Chief Executive Officer, Skokomish Indian Tribe, Skokomish Washington

"We're foresters in that we're stewards," says Tom Strong, Chief Executive Officer of the Skokomish Indian Tribe, which manages 2,000 acres of Washington forests for its 800 tribal members. "We're not cutting and planting, seeking to develop our lands into a commodity. Instead, we're doing it to restore the forest."

Over the past 100 years, the two dams on the North Fork Skokomish River have had a major impact on the entire ecosystem of Skokomish land. "We want to restore the entire Hood Canal watershed," Tom says. The forests are just one part.

Selling wood from Douglas fir trees the tribe selectively thinned will help fund this restoration. "We don't have an endless amount of money," Tom says. "But we would like to think we've got an endless amount of time."

Ben Hayes - Co-owner, Hyla Woods, Cherry Grove, Oregon

Ben Hayes is a sixth-generation forester who manages Hyla Woods, outside Cherry Grove, Oregon, with his father, Peter. He is also a sustainable-forestry consultant. At Hyla Woods, the Hayes experiment with selective thinning and patch cutting, instead of clear-cutting, to foster diversity of tree species, ages, and sizes.

"When you look 100 years out, having greater complexity in terms of species and the structure of the forest, you can increase the forest's resilience in the face of extreme weather and drought," he says.

"We're working toward a model of forestry that you could practice for the perpetual future,” Ben says. “It's a model that lifts up both rural and urban communities and the ecosystems we rely on."

Richard and Ann Hanschu - Owners, Doneen, Forest Grove, Oregon

Ann Hanschu's father first bought land outside Forest Grove, Oregon, in 1956. Ann grew up trailing her father around the forest, learning from him. The Hanschus now have three children, four grandchildren, and five great-grandchildren.

Richard says, "We're planting trees that our grandchildren will see the profits from — not even our children. It's long-range thinking."

"A lot of the timber is older,” Ann adds. “We're laddering it with trees of different age groups — some 30-40 years old, some 10-20 years old — so the land can continue to produce a sustainable amount of wood."

Herman Flamenco - Central Cascades Conservation Forester, The Nature Conservancy, Cle Elum, Washington

"We know historically that the stands we're working on were overstocked," says Herman Flamenco, Central Cascades conservation forester for the Nature Conservancy, of the 50,000 acres outside Cle Elum, Washington, the organization manages. Thinning the trees welcomes in light and biodiversity.

Some loggers in the region worry that this low-impact approach to forestry yields less lumber, and less profit, than clear-cutting. One local outfit took on this labor-intensive challenge, selectively harvesting Doug fir trees from steep slopes.

"Western Washington is wetter. In our dry climate, there's less moisture and increased fire risk," Herman says. "As we look at climate change, it's just going to get dryer. We want to make sure we can keep our forests around."

In the 1950s, back when people wore fancy hats to the airport, PDX’s main terminal had brown terrazzo floors.

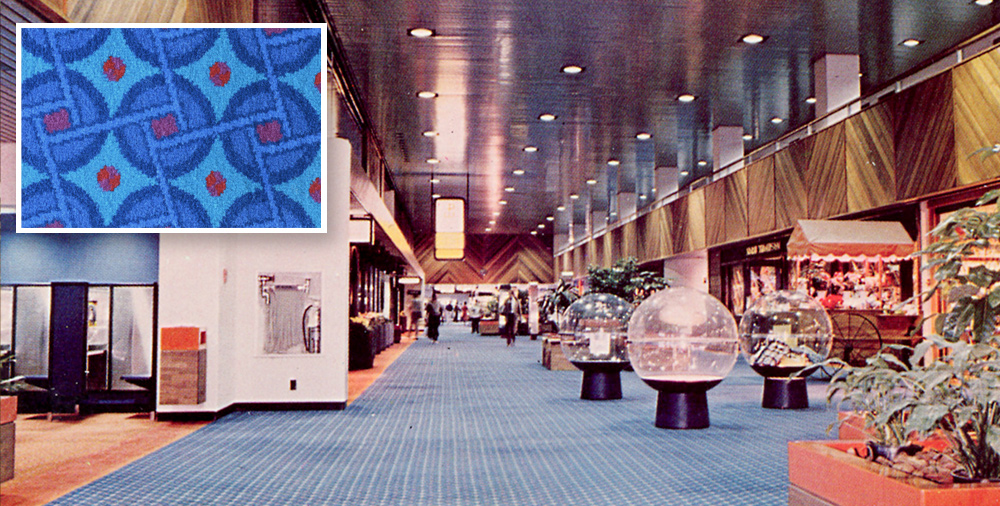

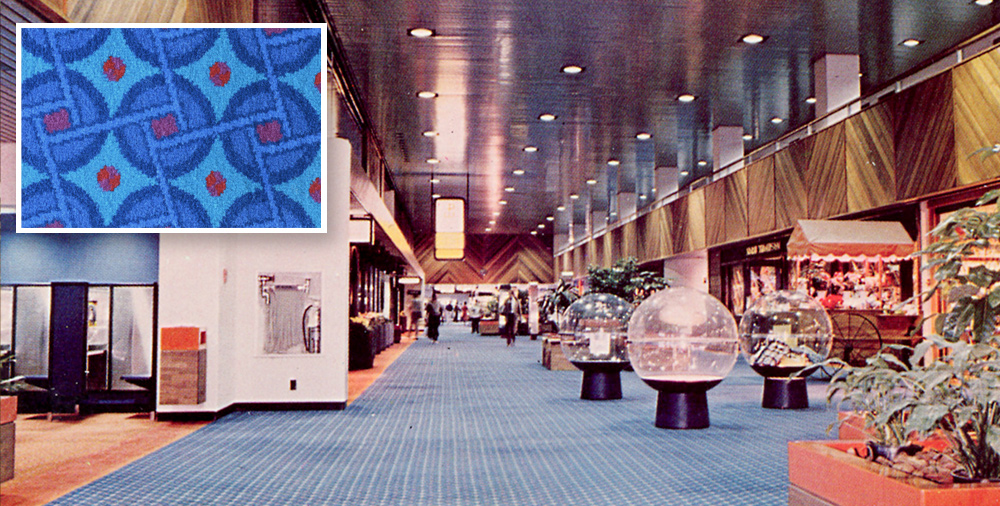

By the 1970s, blue carpet sporting the old Port of Portland logo replaced the terrazzo. The airport was so concerned about keeping the carpet clean that we banned gum-chewing indoors.

In the 1980s, PDX replaced the ski-chalet paneling in the Clocktower Plaza with high ceilings and skylights, but kept the blue carpet.

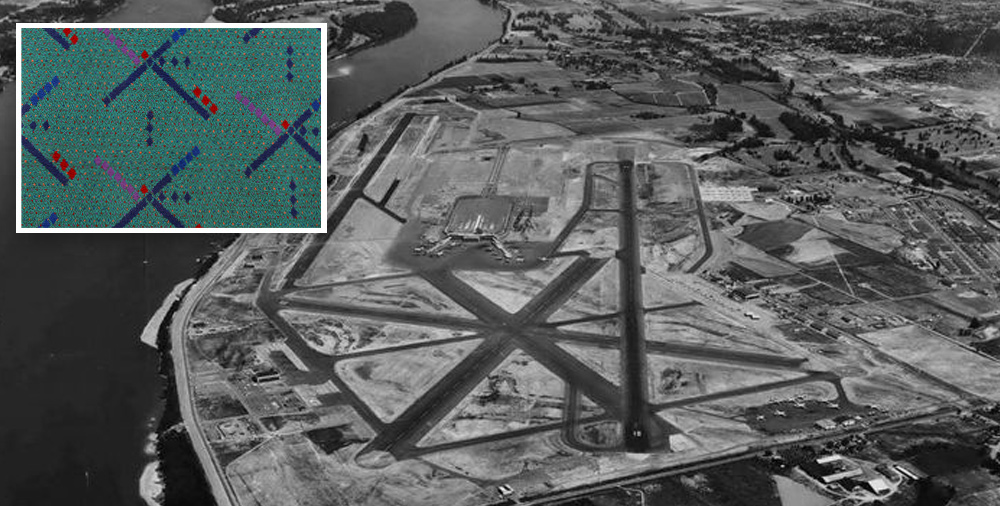

SRG Partnership, a Portland-based architecture firm, designed the pattern for the now-iconic carpet on the layout of the airport runways.

The Clocktower Plaza, post-1988, with the iconic carpet.

The Clocktower Plaza (before its demolition in 2021-22) with the new carpet.

The flexible interior spaces were designed with the future of travel in mind — and to give you plenty of comfortable spots to recharge before your next flight.

Two permanent installations from acclaimed contemporary artist Jacob Hashimoto hang like clouds above the concourse’s common areas.

Shops and restaurants are clustered together like city blocks, with a pedestrian-friendly scale and lots of room to spread out.

PDX’s swanky new bar, Juliett, honors women in aviation with mid-20th-century style, top-class cocktails, and local wines and beers.

Sky-high windows fill the interior with daylight while maximizing the concourse extension’s energy efficiency.

At the east end of the concourse, a wall of windows opens up this epic view of Mt. Hood, where you’ll definitely want to pose for a photo before takeoff.

The Concourse E extension project is the dedicated home for Southwest Airlines at PDX, with six new gates.

Remember the view of Mt. Hood on Concourse E? It’s coming back, brighter than ever.

Tillamook’s menu includes the best of the classics with fried cheese curds and a signature grilled cheese.

Calliope takes its name from one of Oregon’s native hummingbirds and showcases creative and playful keepsakes.

Grab your favorite book, magazine or newspaper at Your Northwest Travel Mart.

Concourse B's 38-foot-high ceilings and 6,900 square feet of windows don't just let light in. They let you watch the airport in action. "I think this airport gave us a chance to celebrate the romance of flight," says Gene Sandoval of ZGF, the architecture firm that designed the new concourse.

ZGF Architects was inspired to bring the Pacific Northwest’s natural world indoors. You can contemplate the plants hanging from the ceiling and the Oregon white-oak walls as you relax in B’s comfy new seats. (Bonus: More power adapters!)

RYAN! Feddersen’s art installation, which fills the concourse, is made up of three interconnected pieces. The “Sentinel” landscapes and abstract “Habitat Tiles” are pictured here.

RYAN! is an enrolled member of the Confederated Tribes of the Colville Reservation. She draws inspiration from the region’s traditions and landscape for these pieces, which include the gently rolling “Cloud Walk” overhead.

Nicole and David Mouton, in partnership with HMSHost, opened an outpost of Portland’s beloved Screen Door Restaurant on Concourse B. Find Screen Door’s legendary fried chicken and waffles here from breakfast until dinnertime.

Sam and Nick Purvis, the brothers behind Good Coffee, source fresh coffee beans and teas from all over the world. Pick up a pastry or a bag of beans, too!

Our new rental car center opened in November 2021.

All rental car brands are now on-site at PDX – no more shuttles to pick up your car.

Perez Westbrooks' colorful digital mural celebrates Northwest flora.

Ben Butler's swirling wood sculpture is made from reclaimed Douglas fir.

The new facility also adds 30 ADA parking spots, more than 30 electric vehicle charging stations, and 2,200 long-term parking spaces to the airport.

Adding more lanes to our new, relocated exit toll plaza helps you leave PDX more quickly.

Every design decision we make is about keeping the heart and soul of PDX intact. You’ll see homages to all the things you love about our city and region in the new airport designs.

You’ll notice subtle nods to the Pacific Northwest landscape throughout the space. Natural light, living trees, and native Oregon foliage may give you the feeling of walking through a park.

The new terminal’s wooden ceiling, made from sustainably grown, local Doug fir, might remind you of daylight filtering through forest canopies.

This will be your new view when entering the spacious ticket lobby at PDX. The nine-acre wood roof is so distinctive you’ll be able to spot it from the air.

The ripples and currents of pristine Northwest rivers inspired the new terminal’s curvy profile.

Expanding the heart of PDX creates more space for our beloved local shops and restaurants — not to mention local humans (and visitors, too).

Sorry, we didn't find any stories with that search term - please try something else.